Designing For CNC: How Millwork Drafting Is Evolving?

Learn how millwork drafting is changing with CNC. Discover what’s new, what matters, and how to create machine-ready drawings.

Millwork drafting is no longer just about clean layouts and construction intent. With CNC machines becoming a core part of fabrication, the drafting process is going through a shift. Traditional shop drawings, once made for skilled hands on the shop floor, are now being tailored for machines that read every line and curve with precision.

This shift isn’t just technical. It changes how drafters think, how they draw, and how they prepare files for production. Line weights, labels, and dimensions still matter, but so do tool paths, material nesting, and machine logic. Drawings must now serve both the shop floor and the CNC interface.

In this article, we’ll look at how millwork drafting is adapting to CNC workflows. We'll cover what's changing, why it matters, and what drafters need to keep in mind when designing for machine production. Let’s start!

Shift from Manual to Machine-Driven Drafting

Millwork drawings were once made with skilled craftsmen in mind. Drafters would focus on showing clear measurements, joinery methods, and finishes. But with CNC machines now playing a bigger role, drawings need to do more than guide a person, they must guide a machine.

CNC machines read digital files. They don’t guess or adjust like a human would. So, drafting today is less about interpretation and more about accuracy. Every line, hole, and curve needs to be machine-readable. That means drafters now need to think like programmers as much as they think like designers.

What CNC-Ready Drawings Look Like?

CNC-ready drawings are built for precision. These files often include clear layers, smart labeling, and formats that work directly with machine software.

Tool paths, for example, show the machine where to cut. Nesting arrangements show how parts fit into a sheet of material to reduce waste. Even small details like corner radii and drill holes must match what the machine can do.

Everything is designed so that once the file is loaded, the machine knows exactly what to do.

Common Drafting Adjustments for CNC Workflows

Drafting for CNC often means adjusting the way details are drawn. Here are a few common changes:

-

Use clean geometry: Machines don’t like broken or overlapping lines.

-

Avoid tiny, tight corners: Tool bits can’t reach them.

-

Simplify where possible: Overly complex shapes slow down the machine and increase the risk of errors.

-

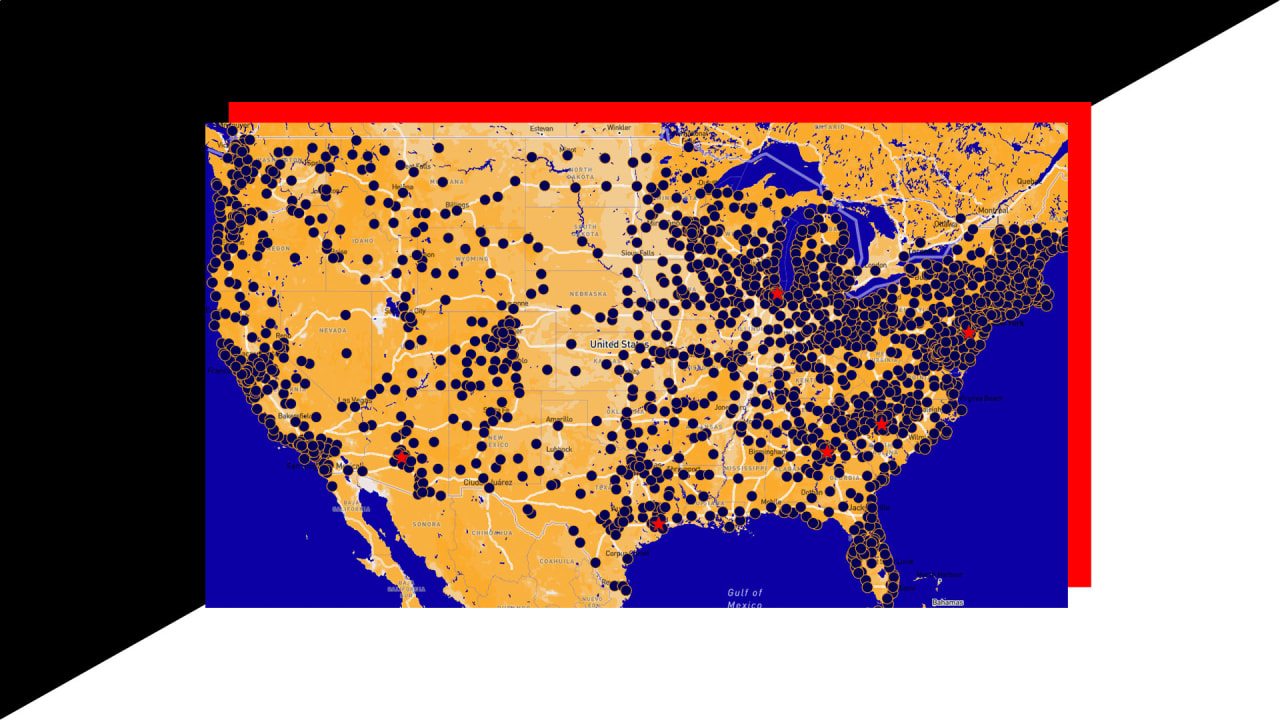

Plan for materials: Arrange parts in a way that saves space and reduces waste.

These changes may seem small, but they make a big difference during production.

Collaboration Between Designers, Drafters, and CNC Programmers

CNC workflows work best when everyone is on the same page. Designers may think about form and function, while drafters focus on details. CNC programmers then turn those details into machine instructions.

Good collaboration helps avoid rework. For example, if a designer adds a feature that’s hard to machine, the drafter can suggest a simpler option. Or, if a programmer spots a problem in the drawing, they can send it back for revision before production begins.

This kind of teamwork improves speed and quality across the board.

Role of Software in CNC-Driven Drafting

Software plays a major role in this process. Tools like AutoCAD, Cabinet Vision, and other CAD/CAM platforms help convert drawings into CNC-compatible files.

These tools allow drafters to set tool paths, assign machining operations, and preview cuts before anything hits the shop floor. Some software even includes nesting tools that arrange parts automatically based on material size.

The goal is to go from drawing to production with as few steps and as few errors as possible.

What does this mean for the Future of Millwork Drafting?

As CNC becomes more common, millwork drafting is shifting toward a more technical process. Drafters need to understand both design and machine behavior. This opens new opportunities for those who can blend the two skill sets.

There’s also less room for guesswork. CNC machines won’t catch design errors or fill in missing details. That’s why precise, machine-ready drafting is no longer optional.

The result? Faster builds, cleaner cuts, and fewer mistakes on the shop floor.

The Final Thoughts

In short, CNC is changing how millwork drawings are made. From the way files are prepared to how teams work together, drafting today looks different from how it did a few years ago. The focus is now on accuracy, clarity, and machine logic.

For drafters and design teams, adapting to this shift isn’t just about using new tools, it’s about thinking in a new way. And those who do will be better prepared for the next generation of custom millwork production.

![https //g.co/recover for help [1-866-719-1006]](https://newsquo.com/uploads/images/202506/image_430x256_684949454da3e.jpg)

![[PATREON EXCLUSIVE] The Power of No: How to Say It, Mean It, and Lead with It](https://tpgblog.com/wp-content/uploads/2025/06/just-say-no.jpg?#)