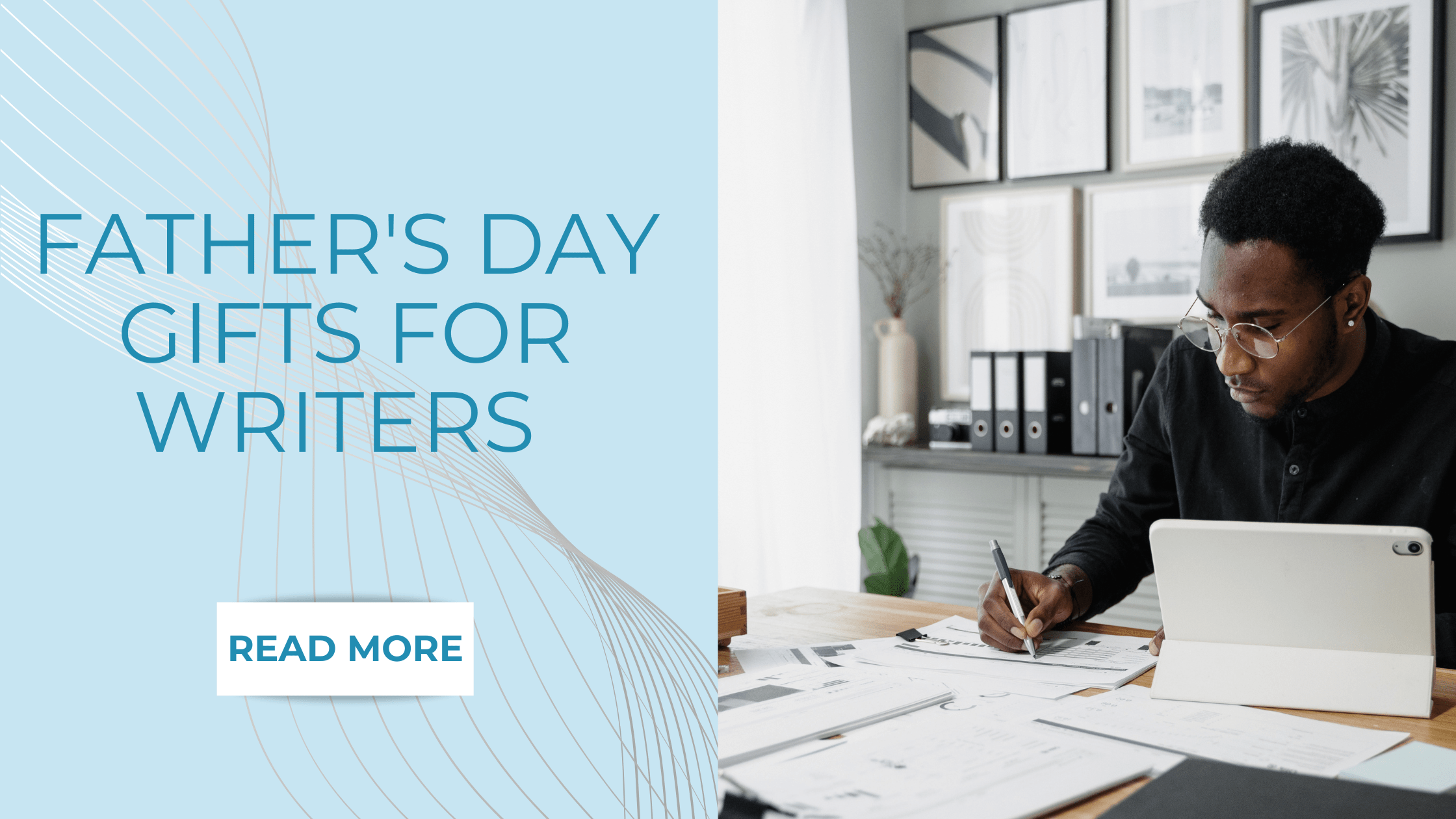

Top Mistakes to Avoid When You Digitize a Logo for Embroidery

Embroidery digitizing is like translating a novel into another language - one wrong move and your beautiful logo becomes an unrecognizable mess.

Embroidery digitizing is like translating a novel into another language - one wrong move and your beautiful logo becomes an unrecognizable mess. I've seen too many businesses waste hundreds on ruined merchandise because of simple digitizing mistakes.

In this guide, we'll walk through the most common (and costly) errors people make when digitize logo for embroidery - and exactly how to avoid them. Whether you're DIY-ing or working with a digitizer, these tips will save you time, money, and frustration.

1. Starting With Low-Quality Artwork

The Mistake: Uploading a blurry JPEG or tiny logo and expecting perfect stitches.

Why It Fails:

- Pixelated edges become jagged stitches

- Low resolution loses detail

- Auto-traced paths create chaotic stitch patterns

The Fix:

- Always provide vector files (AI, EPS, PDF) when possible

- For raster images, use 300+ DPI PNGs

- Simplify complex elements before digitizing

Pro Tip: Zoom your image to 100%. If edges look fuzzy on screen, they'll be worse in thread.

2. Ignoring Fabric Differences

The Mistake: Using the same digitized file for polos, hats, and towels.

Why It Fails:

- Stretchy fabrics need more underlay

- Thick materials require adjusted density

- Terry cloth soaks up stitches differently

The Fix:

- Specify fabric type when ordering digitizing

- Create separate files for different materials

- Always test stitch on actual fabric

Case Study: A restaurant saved $3,000 in uniform replacements after creating separate digitized versions for chef coats (heavy) and server shirts (lightweight).

3. Overcomplicating Small Details

The Mistake: Trying to stitch 0.2" tall text or hairline strokes.

Why It Fails:

- Needles can't replicate ultra-fine details

- Tiny elements get lost in thread bulk

- Text becomes unreadable

The Fix:

- Minimum text height: 0.3" (0.5" ideal)

- Minimum line thickness: 1mm

- Simplify detailed illustrations

Visual Guide:

|

Detail Size |

Stitchability |

|

>0.5" |

Perfect |

|

0.3-0.5" |

Good |

|

<0.3" |

Poor |

4. Skipping the Test Stitch

The Mistake: Ordering 100 embroidered hats without sampling first.

Why It Fails:

- 62% of digitized logos need adjustments after first stitch-out (ETA 2023)

- Fabric behaves differently than screen previews

- Color matching surprises

The Fix:

- Always stitch a sample on scrap fabric

- Check for puckering, registration issues

- Verify thread colors match brand standards

Cost Saver: A tech startup avoided $1,200 in wasted merch by catching digitizing errors in their test stitch.

5. Using Auto-Digitize for Important Logos

The Mistake: Clicking "auto-digitize" and hoping for the best.

Why It Fails:

- Software can't interpret artistic intent

- Misses critical pull compensation

- Creates inefficient stitch paths

The Fix:

- For company logos, always use manual digitizing

- Hire a professional for complex designs

- Reserve auto-digitize for simple shapes

Pro Insight: Even professionals spend 1-4 hours manually editing auto-digitized files.

6. Poor Stitch Type Selection

The Mistake: Using fill stitches where satin would work better.

Common Issues:

- Bulky, stiff logos

- Uneven texture

- Excessive thread use

The Fix:

- Satin stitches: Borders, text (width under 8mm)

- Fill stitches: Large solid areas

- Running stitches: Fine details

Visual Example: A university logo improved dramatically by switching from all-fill to satin stitch lettering.

7. Neglecting Underlay

The Mistake: Jumping straight to top stitches.

Why It Matters:

- Stabilizes fabric

- Prevents show-through

- Improves top stitch appearance

Underlay Types:

- Center run: Basic stabilization

- Edge run: Outlines shapes

- Zigzag: Supports fill areas

- Mesh: Full coverage for large fills

Pro Tip: The stretchier the fabric, the more underlay you need.

8. Incorrect Pull Compensation

The Mistake: Not accounting for fabric movement during stitching.

Results In:

- Gaps between elements

- Misaligned design sections

- Distorted shapes

The Fix:

- Add 10-15% extra width to satin stitches

- Extend fill areas slightly beyond edges

- Test on actual fabric (not just stabilizer)

Industry Standard: Most pros use 0.3-0.5mm pull comp for woven fabrics.

9. Wrong File Format Choices

The Mistake: Only getting a .DST when your machine needs .PES.

Common Formats:

- .PES: Brother machines

- .DST: Tajima/commercial

- .EXP: Melco/Bernina

- .JEF: Janome

The Fix:

- Know your machine's required format

- Request multiple formats if needed

- Keep original vector files for future edits

Pro Move: Save both the embroidery file AND the original digitizing project file.

10. Choosing Price Over Quality

The Mistake: Going with the cheapest digitizing service.

Hidden Costs:

- Multiple revisions needed

- Wasted materials

- Brand damage from poor quality

Smart Spending:

- Expect to pay 15−15−75 for professional digitizing

- Look for free test stitches/revisions

- Check portfolios before buying

ROI Example: A hotel chain saved $8,000/year by investing in quality digitizing that lasted through 50+ washes.

Bonus: Pro Digitizing Checklist

Before finalizing any logo digitizing:

✔ Verify stitch count matches expectations

✔ Check for unnecessary jumps/trims

✔ Confirm color changes are logical

✔ Test on scrap fabric first

✔ Keep a "swatch book" of successful settings

When to DIY vs. Hire a Pro

DIY Digitizing Works For:

- Simple text/geometric designs

- Personal projects

- Learning the craft

Hire a Pro For:

- Company logos

- Complex artwork

- Customer-facing merchandise

- Bulk production

Cost Comparison: While DIY software seems cheaper upfront, professional digitizing averages just 15−15−50 per design - a negligible cost when spread across hundreds of embroidered items.

Final Thoughts: Stitch It Right the First Time

Avoiding these common digitizing mistakes will save you:

- Money (less wasted materials)

- Time (fewer do-overs)

- Stress (no embroidery disasters)

Remember: Your logo represents your brand every time it's worn. Isn't it worth getting it right?

Next Steps:

- Audit your current digitized logos

- Create a fabric-specific settings guide

- Build relationships with trusted digitizers

Got a digitizing horror story or success tip? Share it below!

![https //g.co/recover for help [1-866-719-1006]](https://newsquo.com/uploads/images/202506/image_430x256_684949454da3e.jpg)

![[PATREON EXCLUSIVE] The Power of No: How to Say It, Mean It, and Lead with It](https://tpgblog.com/wp-content/uploads/2025/06/just-say-no.jpg?#)