Everything You Need to Know About Pulp Product Customization

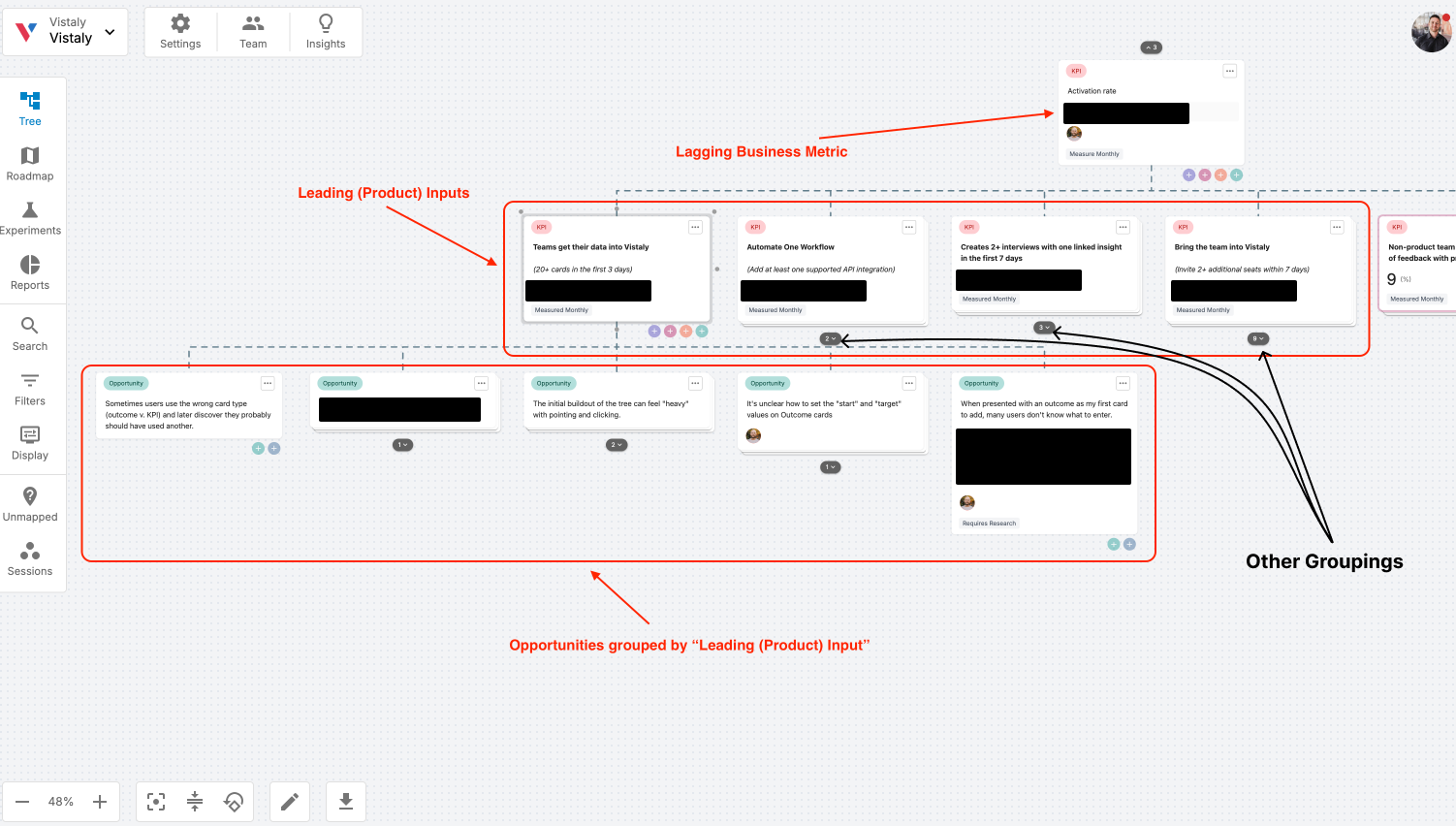

Another crucial element is the mold design. This determines the shape, structure, and functionality of the pulp product.

Pulp products are eco-friendly solutions created from recycled paper, cardboard, or virgin fibers, molded into various forms for packaging, protection, and presentation. Commonly used in industries such as electronics, food and beverage, cosmetics, agriculture, and consumer goods, pulp products are known for their sustainability and cost-effectiveness. These products range from egg trays and protective packaging inserts to molded fiber clamshells and biodegradable containers. Their popularity continues to rise with growing awareness about environmental preservation and a push for greener alternatives to plastic.

Pulp product customization involves tailoring these molded fiber items to meet specific functional, structural, and aesthetic requirements. Businesses are increasingly turning to customized pulp solutions to reinforce their brand identity, enhance product protection, and ensure a snug fit for their goods. Customization extends beyond shape and size—it also includes embossing logos, selecting colors, and designing stackable or space-saving structures. With the right customization strategy, companies can create packaging that not only supports environmental goals but also boosts customer satisfaction and brand recognition.

The Benefits of Pulp Product Customization for Businesses

One of the most significant advantages of pulp product customization is its ability to enhance brand identity. Customized pulp packaging can be designed to include logos, taglines, and even color schemes, which help businesses stand out in a competitive market. Aesthetically appealing and eco-conscious packaging creates a positive first impression and communicates a brand's commitment to sustainability. Especially for retail and e-commerce sectors, where packaging is often the first physical touchpoint with customers, having a distinct customized pulp product can be a game-changer.

From a functional perspective, customized pulp packaging offers superior protection and efficiency. Unlike generic packaging, customized molds are created to fit specific product dimensions, reducing movement during transit and minimizing the risk of damage. This tailored fit not only ensures product safety but can also lead to cost savings through optimized space usage and reduced need for additional protective materials like bubble wrap or foam. With custom solutions, companies can also address unique requirements such as moisture resistance, stackability, and ease of use—all while reducing their environmental footprint.

Key Elements to Consider in Pulp Product Customization

When approaching pulp product customization, it's essential to consider the type of pulp material to be used. Options include recycled paper pulp, virgin wood pulp, bamboo pulp, and sugarcane bagasse, each with distinct characteristics in terms of strength, texture, and biodegradability. Depending on the product being packaged, the right choice of material ensures the final product meets durability and sustainability expectations. For instance, electronics may require sturdier fiber blends for shock absorption, whereas delicate fruits might benefit from lighter, breathable packaging.

Another crucial element is the mold design. This determines the shape, structure, and functionality of the pulp product. A well-thought-out mold not only provides an exact fit for the item but also enhances the unboxing experience, something increasingly important in today’s customer-centric market. Advanced 3D modeling and prototyping tools can assist in visualizing the final design before mass production. Businesses should also factor in post-processing options such as printing, embossing, and coatings to enhance the product’s look and performance without compromising recyclability or compostability.

Technological Advances Driving Pulp Product Customization

Recent technological advancements have significantly elevated the possibilities within pulp product customization. Computer-aided design (CAD) tools now allow for intricate mold designs that previously would have been too complex or costly to produce. These digital tools streamline the customization process, ensuring a high level of precision and reducing lead times. 3D printing is also being used in prototype development, enabling businesses to quickly test and iterate designs before committing to full-scale manufacturing.

Automation in the pulp molding process has further expanded what’s achievable in terms of speed, consistency, and flexibility. Smart machinery can now handle various customization tasks with minimal human intervention, from shaping and drying to trimming and stacking. These improvements not only reduce production costs but also allow for higher volume output without sacrificing quality. Additionally, innovations in pulp chemistry have introduced water-resistant, oil-resistant, and heat-tolerant treatments, enabling customized pulp products to perform in more demanding environments like fast-food packaging or electronics transport.

Sustainable and Marketing Implications of Pulp Product Customization

Sustainability is at the heart of pulp product customization. By choosing biodegradable and compostable materials, businesses contribute to reducing plastic waste and supporting circular economy principles. Customizing pulp products to use just the right amount of material also helps in minimizing waste during production. Some companies even go a step further by utilizing agricultural waste or post-consumer recycled content in their pulp, further lowering their environmental impact. Certification labels like FSC (Forest Stewardship Council) can be added to customized pulp products to showcase a brand’s commitment to responsible sourcing.

Beyond environmental benefits, pulp product customization offers unique marketing advantages. Customized pulp packaging can serve as a powerful storytelling tool, reflecting a company’s values and enhancing customer perception. With growing consumer demand for eco-conscious brands, companies that invest in stylish, well-branded, and sustainable pulp packaging are more likely to foster loyalty and attract environmentally-aware customers. This combination of visual appeal and eco-functionality creates a competitive edge that extends far beyond the shelf, strengthening brand positioning in an increasingly sustainability-driven marketplace.

Conclusion

Pulp product customization is no longer just an add-on service—it's a strategic tool that helps companies align functionality, sustainability, and branding. Whether you're an e-commerce startup looking for eco-friendly unboxing experiences or a manufacturing company seeking efficient protective packaging, tailored pulp solutions can meet diverse business needs. By leveraging advances in design, materials, and automation, businesses can create custom pulp products that deliver on both performance and environmental responsibility.

Understanding the full potential of pulp product customization enables brands to innovate confidently, impress customers, and contribute positively to a greener future. As demand for sustainable practices continues to grow, customized molded fiber packaging will undoubtedly play a central role in shaping the future of responsible business operations.

![https //g.co/recover for help [1-866-719-1006]](https://newsquo.com/uploads/images/202506/image_430x256_684949454da3e.jpg)

![[PATREON EXCLUSIVE] The Power of No: How to Say It, Mean It, and Lead with It](https://tpgblog.com/wp-content/uploads/2025/06/just-say-no.jpg?#)