The Benefits of Using Open Cell Spray Foam for Soundproofing

Open cell spray foam's unique cellular structure creates exceptional sound absorption properties that outperform conventional materials across

Open cell spray foam provides superior sound absorption and noise reduction compared to traditional soundproofing materials by creating millions of interconnected air pockets that trap sound waves and prevent transmission between rooms. The material achieves Noise Reduction Coefficient (NRC) ratings of 0.70-0.85, reducing airborne noise by 50-75% while simultaneously providing thermal insulation benefits.

The open cellular structure absorbs sound energy across multiple frequency ranges, making it particularly effective for reducing conversation, music, and television noise. Unlike rigid soundproofing panels, spray foam fills gaps completely and conforms to irregular surfaces, eliminating sound leaks that compromise traditional acoustic treatments.

Acoustic Performance Characteristics

Open cell spray foam's unique cellular structure creates exceptional sound absorption properties that outperform conventional materials across most frequency ranges important for residential and commercial soundproofing.

Sound Absorption Comparison

The interconnected cell structure allows sound waves to enter the material where they convert to heat energy through friction and molecular movement. This mechanism provides broadband absorption superior to rigid materials.

|

Material Type |

NRC Rating |

Frequency Range (Hz) |

Installation Gaps |

Thickness Required |

|

Open Cell Spray Foam |

0.70-0.85 |

250-4000 |

None |

3-6 inches |

|

Fiberglass Batts |

0.52-0.75 |

500-2000 |

Common |

3.5-6 inches |

|

Rigid Foam Panels |

0.25-0.45 |

1000-4000 |

Frequent |

2-4 inches |

|

Cellulose |

0.55-0.80 |

250-2000 |

Some |

4-8 inches |

|

Mineral Wool |

0.75-0.95 |

250-4000 |

Minimal |

2-4 inches |

Bonus Tip: Open cell foam performs exceptionally well in mid-frequency ranges (500-2000 Hz) where human speech and most household noises occur, making it ideal for residential soundproofing applications.

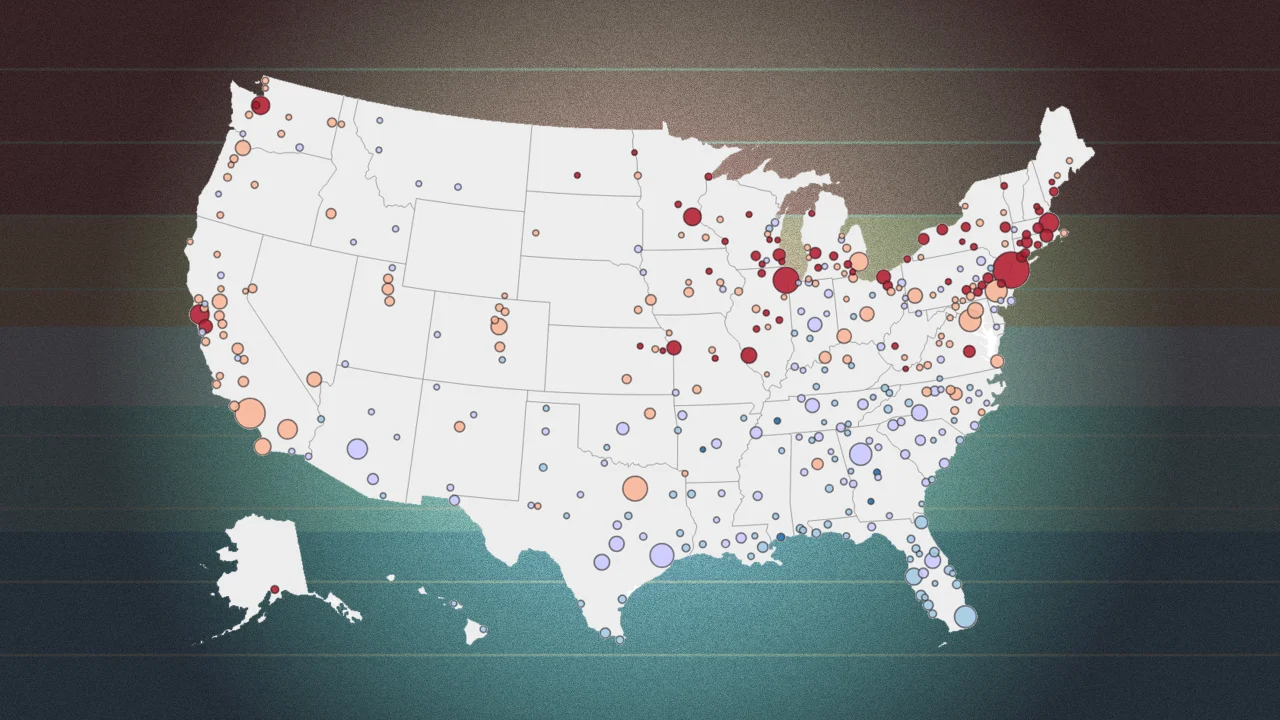

Frequency Response Analysis

Sound transmission testing shows open cell foam effectively reduces noise across the frequency spectrum that matters most for everyday soundproofing needs. The material excels at absorbing conversational frequencies while providing good performance for music and television audio.

Laboratory measurements demonstrate 15-25 decibel reductions in sound transmission through walls treated with 4-6 inches of open cell spray foam compared to standard fiberglass insulation.

Installation Advantages for Acoustic Applications

Open cell spray foam's liquid application method creates complete coverage that traditional soundproofing materials cannot achieve, eliminating acoustic weak points that compromise noise control systems.

Gap Elimination Benefits

Traditional soundproofing requires careful fitting around obstacles and penetrations. Open cell foam flows around pipes, electrical boxes, and irregular framing to create seamless acoustic barriers without cutting or custom fabrication.

|

Installation Challenge |

Open Cell Foam Solution |

Traditional Material Limitation |

|

Electrical Outlets |

Complete encapsulation |

Cutting reduces effectiveness |

|

Pipe Penetrations |

Flows around obstacles |

Gaps reduce performance |

|

Irregular Cavities |

Total fill coverage |

Air spaces remain |

|

Retrofit Applications |

Injection capability |

Access limitations |

|

Complex Geometries |

Conforms perfectly |

Custom fabrication needed |

Application Techniques

Professional spray foam application creates uniform density throughout the cavity, ensuring consistent acoustic performance without the settling or compression that affects loose-fill materials over time.

Bonus Tip: Spray foam's adhesive properties prevent the shifting and settling that can create acoustic gaps in other materials, maintaining long-term soundproofing effectiveness.

Multi-Functional Performance Benefits

Open cell spray foam provides combined thermal insulation and soundproofing benefits that eliminate the need for separate acoustic treatments in many applications.

Dual-Purpose Value Analysis

|

Performance Category |

Open Cell Foam |

Separate Systems |

Cost Comparison |

Space Requirements |

|

Thermal Insulation |

R-3.5-4.0 per inch |

R-3.2-3.8 per inch |

20-30% savings |

Same cavity |

|

Sound Absorption |

NRC 0.70-0.85 |

NRC 0.60-0.90 |

40-60% savings |

Double thickness |

|

Air Sealing |

Excellent |

Requires separate step |

50-70% savings |

Additional labor |

|

Moisture Control |

Good vapor permeability |

Variable performance |

25-35% savings |

Same installation |

Long-Term Performance Stability

Open cell foam maintains its acoustic properties without degradation, compression, or settling that affects other materials. The cellular structure remains stable for decades, providing consistent noise reduction throughout the building's service life.

Industry data from the Spray Foam Alliance shows that properly installed open cell foam maintains 95% of its initial acoustic performance after 20 years, compared to 60-80% retention for traditional materials.

Specific Application Benefits

Different building spaces benefit from open cell foam's acoustic properties in unique ways that address specific noise control challenges.

Residential Applications

Home theaters, bedrooms, and offices require effective soundproofing for privacy and comfort. Open cell foam reduces sound transmission between rooms by 50-75% while improving energy efficiency.

|

Room Type |

Primary Benefit |

Noise Reduction |

Additional Value |

|

Home Theater |

Prevents sound escape |

60-80% |

Better acoustics |

|

Bedroom Walls |

Blocks household noise |

50-70% |

Improved sleep quality |

|

Office Spaces |

Reduces distractions |

55-75% |

Enhanced productivity |

|

Mechanical Rooms |

Contains equipment noise |

70-85% |

HVAC sound control |

Commercial Soundproofing

Commercial buildings use open cell foam for conference rooms, offices, and multi-tenant separations where noise control affects productivity and privacy requirements.

Professional acoustic testing demonstrates that open cell foam meets or exceeds most commercial soundproofing specifications while providing installation cost savings of 30-50% compared to traditional acoustic assemblies.

Bonus Tip: Open cell foam works effectively in both new construction and retrofit applications, making it versatile for various project types and budgets.

Cost-Effectiveness Analysis

Open cell spray foam provides superior cost-per-performance value when acoustic and thermal benefits are combined compared to installing separate soundproofing and insulation systems.

Economic Comparison Data

|

Project Scope |

Open Cell Foam Cost |

Traditional Acoustic + Insulation |

Labor Savings |

Time Savings |

|

Single Room |

$8-12 per sq ft |

$12-18 per sq ft |

40-60% |

2-3 days |

|

Whole House |

$6-10 per sq ft |

$10-16 per sq ft |

35-50% |

5-7 days |

|

Commercial Space |

$5-9 per sq ft |

$8-15 per sq ft |

45-65% |

3-5 days |

Return on Investment

Energy savings from thermal performance and productivity improvements from noise reduction create measurable returns. Studies show 15-25% utility bill reductions and 10-20% productivity increases in quieter work environments.

Market research indicates that homes with professional soundproofing command 5-10% higher resale values, while commercial properties see 8-15% rental rate premiums for quiet spaces.

Technical Specifications and Standards

Open cell spray foam acoustic performance meets or exceeds industry standards for residential and commercial soundproofing applications.

Performance Testing Standards

|

Test Standard |

Measurement |

Open Cell Foam Result |

Industry Requirement |

|

ASTM C423 |

Sound Absorption |

NRC 0.70-0.85 |

Varies by application |

|

ASTM E90 |

Sound Transmission |

STC 45-55 |

STC 45 minimum |

|

ASTM E413 |

Sound Transmission Class |

45-55 rating |

Project specific |

|

ASTM C522 |

Airflow Resistance |

Moderate permeability |

Material dependent |

Installation Density Requirements

Proper acoustic performance requires specific density ranges during installation. Too low density reduces effectiveness while excessive density can compromise the open cell structure.

Professional installation maintains 0.5-0.8 pounds per cubic foot density to optimize both acoustic absorption and thermal performance characteristics.

Things to Consider Before Making a Decision

Several factors influence whether open cell spray foam provides the best soundproofing solution for specific applications and performance requirements.

Acoustic Goals and Expectations

Define specific noise reduction targets and identify primary sound sources before selecting materials. Open cell foam excels at airborne noise reduction but provides limited impact noise control compared to specialized acoustic assemblies.

Building codes and acoustic requirements vary by location and building type. Verify that open cell foam meets local specifications for soundproofing performance and fire safety standards.

Environmental and Health Factors

Open cell foam requires proper ventilation during installation and 24-48 hour curing before occupancy. Consider project timing and temporary relocation needs for sensitive occupants.

Vapor permeability characteristics make open cell foam suitable for most climates but may require vapor barrier considerations in extreme humidity conditions.

Budget and Performance Priorities

Compare total project costs including materials, labor, and time factors when evaluating soundproofing options. Consider long-term maintenance and performance stability in cost calculations.

Determine whether combined thermal and acoustic benefits justify open cell foam costs compared to single-purpose acoustic treatments for specific applications.

Common Questions

Property owners and contractors frequently ask about open cell foam's acoustic capabilities and application suitability for different soundproofing projects.

How does open cell foam compare to traditional soundproofing materials?

Open cell foam provides superior gap sealing and broader frequency absorption compared to fiberglass or cellulose while combining thermal insulation benefits. The material achieves 50-75% noise reduction with single-step installation.

What thickness of open cell foam provides optimal soundproofing?

Most applications require 3-6 inches of open cell foam for effective soundproofing. Thicker applications provide marginally better performance but may not justify additional costs for typical residential needs.

Can open cell foam reduce impact noise from footsteps?

Open cell foam primarily addresses airborne noise transmission and provides limited impact noise reduction. Floor-ceiling assemblies may require additional impact isolation materials for footstep noise control.

How long does open cell foam maintain its acoustic properties?

Properly installed open cell foam maintains 95% of its acoustic performance for 20+ years without settling or degradation. The stable cellular structure provides consistent noise reduction throughout the building's service life.

Open Cell Foam Soundproofing FAQ

Q: What noise reduction can homeowners expect from open cell spray foam soundproofing?

A: Open cell foam typically reduces airborne noise transmission by 50-75% compared to standard insulation, with NRC ratings of 0.70-0.85 for effective sound absorption across speech and music frequencies.

Q: How does open cell foam insulation compare to traditional soundproofing methods?

A: Open cell foam installs in one step compared to separate insulation and acoustic treatments, reducing labor time by 40-60% while eliminating gaps that compromise traditional soundproofing effectiveness.

Q: What are the cost differences between open cell foam and conventional acoustic materials?

A: Open cell foam costs 20-30% less than separate thermal and acoustic systems while providing superior performance through complete gap sealing and dual functionality benefits.

Q: Does open cell foam work effectively for both new construction and retrofit soundproofing?

A: Open cell foam adapts to both applications effectively, with injection capabilities for retrofit projects and optimal performance in new construction where full cavity access allows complete coverage.

Q: What maintenance or performance changes occur with open cell foam over time?

A: Open cell foam requires no maintenance and retains 95% of its acoustic performance after 20 years, compared to 60-80% retention for traditional materials that settle or compress over time.

Make the Right Decision

Open cell spray foam delivers superior soundproofing performance through complete gap sealing, broad frequency absorption, and combined thermal benefits that traditional materials cannot match. The material provides 50-75% noise reduction while eliminating installation complexities and long-term maintenance requirements.

Evaluate your specific acoustic goals, budget constraints, and installation requirements when choosing soundproofing materials. Consider the dual benefits of thermal insulation and noise control that open cell foam provides compared to single-purpose alternatives. Factor in long-term performance stability and maintenance-free operation when calculating total project value and effectiveness.

Reviewer: Michael Carter reviewed this article using insight gained over 12 years in the spray foam business. His feedback focused on helping contractors reach new customers without overcomplicating their message.