How Does the Sublimation Printing Process Work from Concept to Creation?

Explore the sublimation printing process in Surat from concept to creation. Learn how 16-head sublimation printers deliver vibrant, high-quality prints on various materials. Discover the benefits of this innovative printing technology for businesses and creatives alike!

Sublimation printing has revolutionized the way we think about printing, especially in vibrant markets like Surat. This innovative technique allows for high-quality, full-color prints on a variety of materials, making it a popular choice for businesses and creatives alike. In this blog, we will explore the sublimation printing process from concept to creation, with a particular focus on sublimation printing in Surat.

Understanding Sublimation Printing

Before diving into the process, it’s essential to understand what sublimation printing is. Sublimation printing is a digital printing technology that uses heat to transfer dye onto materials such as fabric, plastic, or metal. The process involves turning solid dye into gas without passing through a liquid state, allowing the dye to bond with the material at a molecular level. This results in vibrant colors and durable prints that are resistant to fading and cracking.

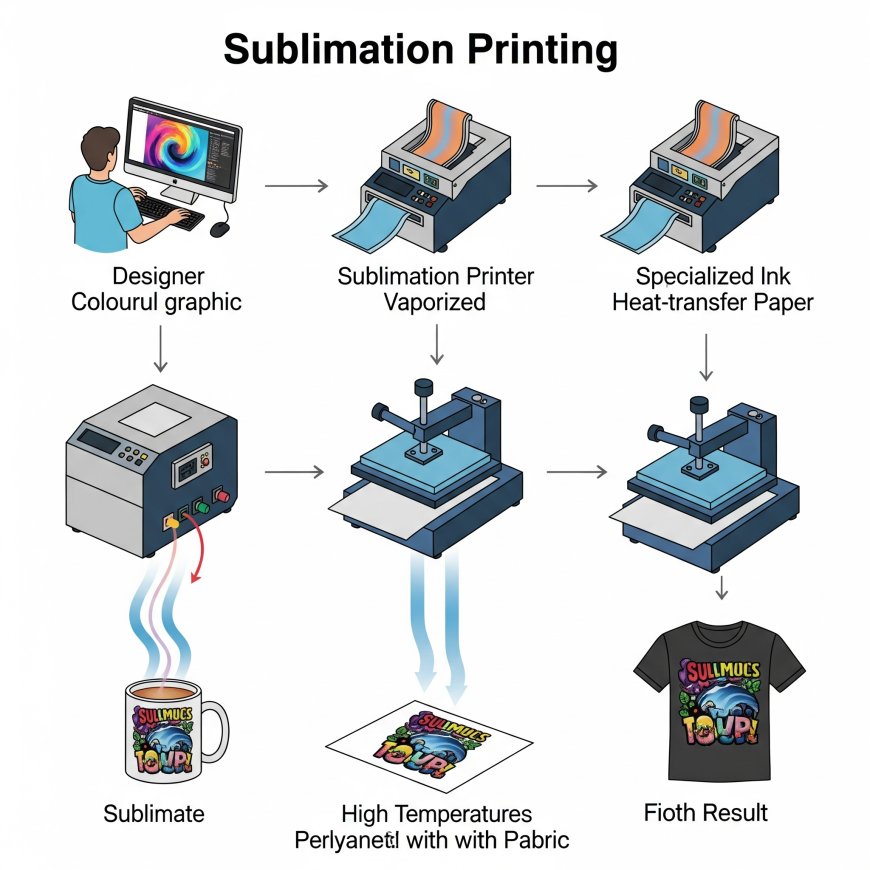

Step 1: Conceptualization

The sublimation printing process begins with a concept. Whether you are designing custom apparel, promotional items, or personalized gifts, the first step is to create a design that reflects your vision. This can be done using graphic design software such as Adobe Illustrator or CorelDRAW.

When designing for sublimation printing, it’s crucial to consider the colors and patterns you want to use. Since sublimation works best on white or light-colored substrates, your design should take this into account. Additionally, it’s important to use high-resolution images to ensure that the final print is sharp and clear.

Step 2: Preparing the Design

Once the design is finalized, the next step is to prepare it for printing. This involves converting the design into a format that the sublimation printer can read, typically a raster image format like PNG or JPEG.

During this stage, it’s also essential to mirror the design. Since sublimation printing transfers the image onto the substrate in reverse, mirroring the design ensures that the final product appears correctly.

Step 3: Printing the Design

With the design prepared, it’s time to print. Sublimation printers use special dye-sublimation inks that are designed to turn into gas when heated. The printer applies the ink onto a transfer paper, which will later be used to transfer the design onto the substrate.

When it comes to sublimation printing in Surat, many businesses invest in high-quality 16-head sublimation printers. These printers are capable of producing vibrant colors and intricate details, making them ideal for a wide range of applications. The printing process typically involves the following steps:

- Loading the Transfer Paper: The transfer paper is loaded into the sublimation printer.

- Printing the Design: The printer applies the dye-sublimation ink onto the transfer paper, creating a mirror image of the design.

- Drying the Ink: The printed transfer paper is allowed to dry, ensuring that the ink is set before the transfer process begins.

Step 4: Preparing the Substrate

While the design is being printed, it’s essential to prepare the substrate that will receive the print. Sublimation works best on materials that are coated with a polymer or are made from polyester. Common substrates include:

- Polyester fabrics (e.g., t-shirts, banners)

- Mugs and drinkware

- Phone cases

- Metal sheets

- Hardboard

Before transferring the design, the substrate should be cleaned to remove any dust or oils that could affect the adhesion of the dye.

Step 5: Heat Transfer

The heat transfer process is where the magic happens. This step involves using a heat press to transfer the design from the transfer paper to the substrate. The heat press applies both heat and pressure, causing the dye to sublimate and bond with the material.

Here’s how the heat transfer process works:

- Setting Up the Heat Press: The heat press is preheated to the appropriate temperature, typically between 350°F to 400°F (175°C to 200°C), depending on the substrate.

- Positioning the Transfer Paper: The printed transfer paper is placed face down on the substrate.

- Applying Heat and Pressure: The heat press is closed, applying pressure for a specific duration (usually 30-60 seconds).

- Cooling Down: After the time is up, the heat press is opened, and the substrate is allowed to cool before removing the transfer paper.

Step 6: Finishing Touches

Once the transfer is complete, the final product is inspected for quality. This includes checking for color accuracy, clarity, and any imperfections. If necessary, additional finishing touches can be applied, such as trimming edges or adding protective coatings.

Advantages of Sublimation Printing

Sublimation printing offers several advantages, making it a preferred choice for many businesses in Surat:

- Vibrant Colors: The dye-sublimation process produces bright, vivid colors that are difficult to achieve with other printing methods.

- Durability: Sublimated prints are resistant to fading, cracking, and peeling, ensuring that the designs last for a long time.

- Versatility: Sublimation can be used on a wide range of materials, allowing for endless creative possibilities.

- Eco-Friendly: The sublimation process is relatively eco-friendly, as it produces minimal waste and uses water-based inks.

Conclusion

Sublimation printing is a fascinating process that transforms concepts into vibrant, high-quality creations. From the initial design to the final product, each step plays a crucial role in ensuring that the end result meets the desired standards. In Surat, where creativity and innovation thrive, sublimation printing has become a popular choice for businesses looking to make a mark in the market. By understanding the sublimation printing process, you can harness its potential to bring your ideas to life and stand out in a competitive landscape. Whether you’re a business owner or a creative individual, sublimation printing offers endless possibilities for expression and innovation.