Why your next bottle of shampoo might come in a soda can

When a Swedish startup set out to make personal care packaging more sustainable, it turned to an unexpected source of inspiration: aluminum cans. Meadow, the company behind the concept, created a refill system that seals shampoo, lotion, and other products inside aluminum cans. Unlike soda, there’s no pull tab—the aluminum cartridge, called Kapsul, has a solid lid. But when you insert the can into Meadow’s reusable pump and twist on the top, the device pierces the lid with a clean, satisfying pop. When you’ve used up the product, the aluminum can be easily recycled. “We knew that we would not be able to develop a totally new packaging solution,” says Victor Ljungberg, Meadow’s CEO and cofounder. “We don’t have the time and we can’t afford to build totally new infrastructure. We need to look at what we have.” [Photo: Meadow] They knew that aluminum beverage cans had a high recycling rate—in Sweden, it’s around 90%. In the U.S., it’s a much lower 43%. But that’s still more than triple the recycling rate for plastic packaging. Aluminum can also be recycled repeatedly without losing any quality, unlike plastic. “The aluminum beverage can, the most recycled container, already exists on the market,” Ljungberg says. “But the whole industry around this has been focused on one thing—to use that container for food-grade content. We asked ourselves, okay, what is it that we need to do to take it into new categories such as personal care, pharma, home care, and others?” [Photo: Meadow] For safety reasons, they didn’t want to put soap in a can that someone might mistake for a drink. That’s why the team designed the lid to only open when it’s inside the reusable dispenser. The design also makes it easier to use than typical refills that have to be poured into a container, Ljungberg argues. (The company calls the packaging “prefills” since they’re already ready to use.) Many refills also currently come in thin plastic film that ends up in the trash. Of course, there are other ways to ditch plastic packaging. Companies like Kitsch make shampoo in bar form, for example, so it only needs a small paper box. But Ljungberg believes that many consumers aren’t quite ready for that much change. [Photo: Meadow] “We need to admit that there is a very established single-use culture among people all over the planet,” he says. “With what we do, we meet consumers where they are, saying that we are not forcing them to change behavior too much. Instead, they will buy the cans on the shelf just as they buy goods today.” [Photo: Meadow] The startup partnered with DRT, the Ohio-based company that invented the first pull-tab cans, as well as Ball Corporation, the world’s largest can manufacturer. Ball Corp is also one of the company’s minority investors. (The startup has raised around $15 million in seed funding so far.) Because it’s possible to make the cans on existing equipment in factories, the packaging can easily scale up. Brands can add their own branding to the cans and dispensers, paying a licensing fee to use the system. Companies like Ikea or Muji could also potentially make universal dispensers. Nuniq, a Swiss personal care company that avoids plastic packaging, recently started using Meadow’s system for products like cleanser and body lotion. More brands will soon follow when Meadow launches in the U.K. this fall.

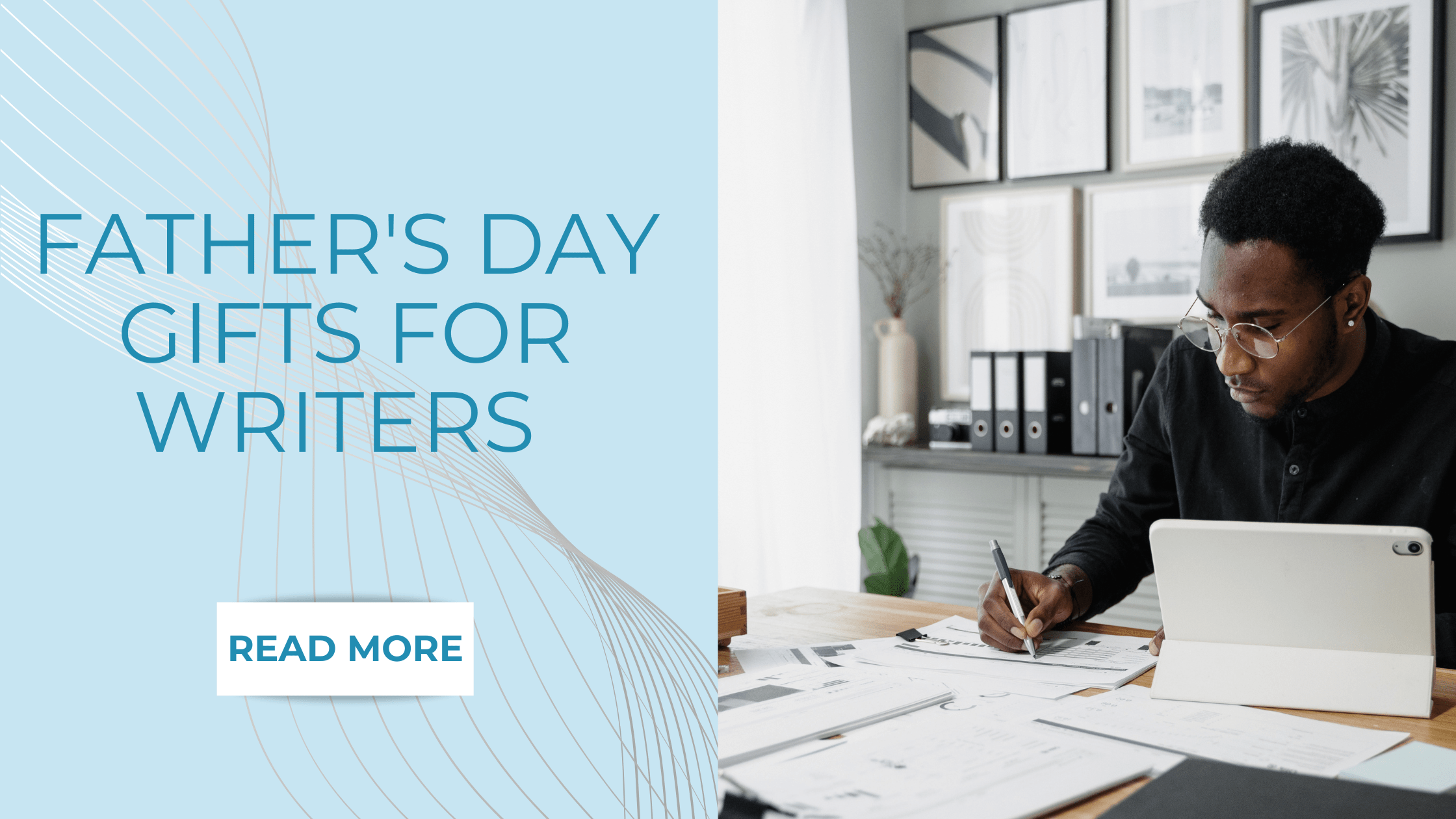

When a Swedish startup set out to make personal care packaging more sustainable, it turned to an unexpected source of inspiration: aluminum cans.

Meadow, the company behind the concept, created a refill system that seals shampoo, lotion, and other products inside aluminum cans. Unlike soda, there’s no pull tab—the aluminum cartridge, called Kapsul, has a solid lid. But when you insert the can into Meadow’s reusable pump and twist on the top, the device pierces the lid with a clean, satisfying pop. When you’ve used up the product, the aluminum can be easily recycled.

“We knew that we would not be able to develop a totally new packaging solution,” says Victor Ljungberg, Meadow’s CEO and cofounder. “We don’t have the time and we can’t afford to build totally new infrastructure. We need to look at what we have.”

They knew that aluminum beverage cans had a high recycling rate—in Sweden, it’s around 90%. In the U.S., it’s a much lower 43%. But that’s still more than triple the recycling rate for plastic packaging. Aluminum can also be recycled repeatedly without losing any quality, unlike plastic.

“The aluminum beverage can, the most recycled container, already exists on the market,” Ljungberg says. “But the whole industry around this has been focused on one thing—to use that container for food-grade content. We asked ourselves, okay, what is it that we need to do to take it into new categories such as personal care, pharma, home care, and others?”

For safety reasons, they didn’t want to put soap in a can that someone might mistake for a drink. That’s why the team designed the lid to only open when it’s inside the reusable dispenser. The design also makes it easier to use than typical refills that have to be poured into a container, Ljungberg argues. (The company calls the packaging “prefills” since they’re already ready to use.) Many refills also currently come in thin plastic film that ends up in the trash.

Of course, there are other ways to ditch plastic packaging. Companies like Kitsch make shampoo in bar form, for example, so it only needs a small paper box. But Ljungberg believes that many consumers aren’t quite ready for that much change.

“We need to admit that there is a very established single-use culture among people all over the planet,” he says. “With what we do, we meet consumers where they are, saying that we are not forcing them to change behavior too much. Instead, they will buy the cans on the shelf just as they buy goods today.”

The startup partnered with DRT, the Ohio-based company that invented the first pull-tab cans, as well as Ball Corporation, the world’s largest can manufacturer. Ball Corp is also one of the company’s minority investors. (The startup has raised around $15 million in seed funding so far.) Because it’s possible to make the cans on existing equipment in factories, the packaging can easily scale up.

Brands can add their own branding to the cans and dispensers, paying a licensing fee to use the system. Companies like Ikea or Muji could also potentially make universal dispensers. Nuniq, a Swiss personal care company that avoids plastic packaging, recently started using Meadow’s system for products like cleanser and body lotion. More brands will soon follow when Meadow launches in the U.K. this fall.

![https //g.co/recover for help [1-866-719-1006]](https://newsquo.com/uploads/images/202506/image_430x256_684949454da3e.jpg)

![[PATREON EXCLUSIVE] The Power of No: How to Say It, Mean It, and Lead with It](https://tpgblog.com/wp-content/uploads/2025/06/just-say-no.jpg?#)