Consumers Are Gaining the Right to Repair — Are You Ready?

Adam Howling/Ikon Images Vendors of software-infused goods have increasingly used digital control over their products to capture additional post-sales value in recent years, such as when they require subscriptions to keep appliances operable or when they remotely limit owners’ ability to fix products when they break. You fixed your broken smartphone with a noncertified screen? […]

Adam Howling/Ikon Images

Vendors of software-infused goods have increasingly used digital control over their products to capture additional post-sales value in recent years, such as when they require subscriptions to keep appliances operable or when they remotely limit owners’ ability to fix products when they break.

You fixed your broken smartphone with a noncertified screen? The manufacturer disabled it. You wanted to keep using features of the smart bassinet you bought for your newborn? You had to subscribe to a monthly service plan. Consumers have paid for technology-enhanced goods but do not always enjoy what most consider to be full rights of ownership. And they are becoming increasingly unhappy about it.

Deere & Co.’s use of software in its tractors to boost post-sales revenue has won the regard of business strategists. But in January, its digital control of service and repairs resulted in a lawsuit filed by the U.S. Federal Trade Commission and the attorneys general of two heavily agricultural states, Illinois and Minnesota. The suit alleges that the company has illegally limited the ability of farmers and independent service providers to repair Deere equipment.

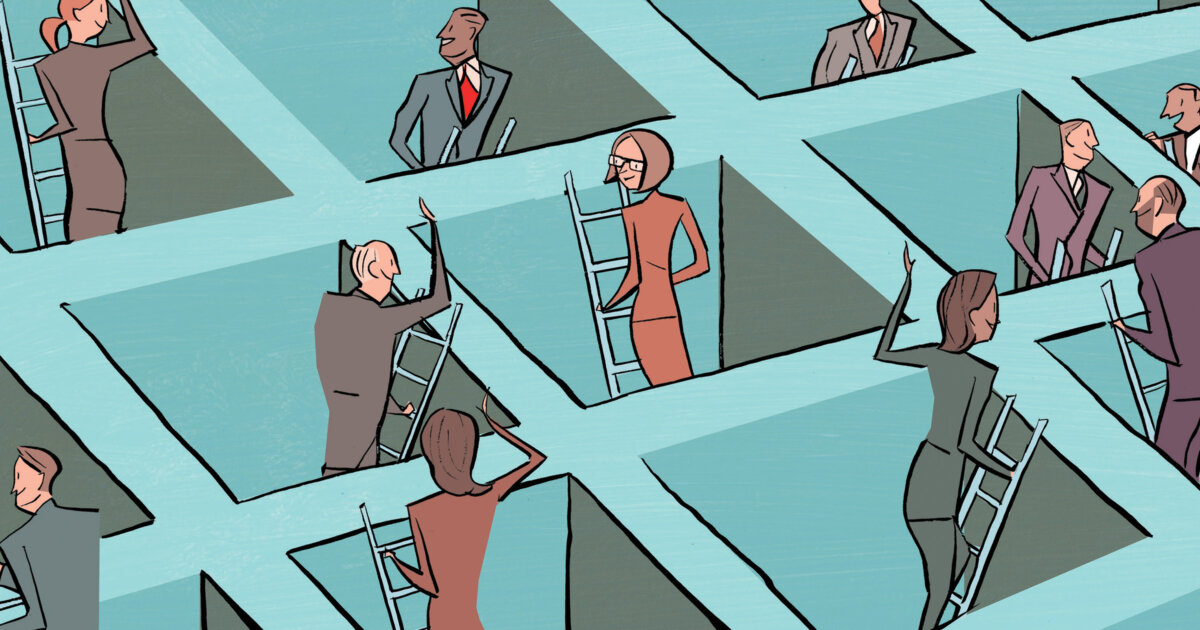

Deere & Co.’s case shows that the legal landscape is changing. Consumers and their advocates who are reasserting traditional rights of ownership are behind new legislation ensuring the right to repair one’s own devices. While rules differ across jurisdictions, they typically require companies to permit product owners to make modifications, customizations, or repairs to the products themselves, or via an independent repair shop, without negative consequences. Right-to-repair laws have passed in California, Colorado, Maine, Massachusetts, Minnesota, New York, and Oregon, and bills are currently active in 30 state legislatures. The European Union adopted a new set of right-to-repair rules in 2024.

The emerging regulatory landscape presents an opportunity for technology manufacturers to redefine their relationship with consumers as a preferred service provider. Rather than use the kind of technological lock-ins and restrictive terms we found in our study of Apple’s maneuvers in the iPhone service market (published in 2024 in MIS Quarterly), companies must address three challenges.

1. Develop a service-centric business model. Many manufacturers build their business models around product sales — and their strategies for extracting post-sales revenue are often designed to protect their control of their product, not to nurture their relationship with customers.

Companies with a service-centric business model put customer experience at the core and focus on solutions that satisfy their technology consumers’ needs not only before but also after selling the product. Best Buy’s Geek Squad unit, for example, diagnoses and repairs all sorts of consumer electronics and treats service as a customer touchpoint and an opportunity to deepen the relationship long after the point of sale. Staying close to the customer allows the company to understand demands and needs, which positions it well to offer additional aftermarket services that enrich customers’ product experiences.

Companies that have collected service revenue by locking customers into rigid service or maintenance schemes need to reimagine service as a competitive business, because it will become only more so as regulations knock down barriers to entry. That means putting customer solutions, not product sales or control, at the center of the business.

2. Rethink product design with repair in mind. Manufacturers will need to evaluate their products for repairability. Are their devices built around proprietary components and architectures, or are they based on shared standards and readily accessible components? What product characteristics currently limit customers or third-party service providers from performing repairs or maintenance? Apple, for example, built its iPhone around proprietary hardware (such as Apple Lightning connectors) and software (e.g., Apple iOS), meaning that the company controls both sourcing and modification of these components. Samsung phones, on the other hand, rely on Google’s open Android smartphone architecture, which makes it easier for customers and third-party complementors to bundle third-party content, parts, or apps with the devices.

Product manufacturers have often taken the proprietary route to maintain control of the product experience, but they will need to cede some control in order to empower product owners to exercise repair rights. In particular, some new legislation stipulates that interfaces must be standardized and open, such as the EU requirement for USB-C charging ports for all mobile technology components in products.

The legislative push for more standardization and repairability will require product vendors to find new cost-effective ways to redesign their products. One strategy could involve the formation of alliances between traditional competitors. The Power-for-All Alliance, for example, includes several of the biggest manufacturers of power tools and gardening products in a joint effort to create a standardized battery platform across different brands, which means users can more easily and conveniently reuse and repair battery packs for various tools and devices, while the manufacturers enjoy benefits from standardization and consolidation of product development and after-sales services.

3. Build analytics into products to gain an edge in services. The implicit promise of an original manufacturer’s service offerings is that the company knows the product better than anyone else. With analytics directly built into the products to monitor product performance, manufacturers can deliver on that promise, for example, by diagnosing maintenance issues before a customer suffers a product failure. A courtesy notification from the manufacturer that a component is nearing the end of its useful life could include a prompt for customers to set up a service appointment and keep that additional revenue in-house.

Product-in-use analytics also provide manufacturers with crucial insight into patterns of user behavior and allow them to monitor product health trends across the installed base. That data can inform predictions about future demand for maintenance, repair, or product replacement and help manufacturers organize service offerings to meet current needs.

The proliferation of right-to-repair legislation will change how technology companies compete for services in the aftermarket. Empowering customers by making products repairable and embedding analytics into the products themselves will allow technology manufacturers to build service-centricity into their business models.

![How to Use GA4 to Track Social Media Traffic: 6 Questions, Answers and Insights [VIDEO]](https://www.orbitmedia.com/wp-content/uploads/2023/06/ab-testing.png)

![How Human Behavior Impacts Your Marketing Strategy [Video]](https://contentmarketinginstitute.com/wp-content/uploads/2025/03/human-behavior-impacts-marketing-strategy-cover-600x330.png?#)

![How to Make a Content Calendar You’ll Actually Use [Templates Included]](https://marketinginsidergroup.com/wp-content/uploads/2022/06/content-calendar-templates-2025-300x169.jpg?#)

![Building A Digital PR Strategy: 10 Essential Steps for Beginners [With Examples]](https://buzzsumo.com/wp-content/uploads/2023/09/Building-A-Digital-PR-Strategy-10-Essential-Steps-for-Beginners-With-Examples-bblog-masthead.jpg)