The Science of Custom Butcher Paper in Prototyping

The benefits of custom butcher paper in product development become clear as this tool allows efficient and environmentally friendly prototyping among various business sectors.

People usually consider foam along with plastic and cardboard during the prototyping phase. A subtle industry transformation is currently underway while using butcher paper as its covering. This flexible material has caught the attention of designers who work together with engineers as well as creative professionals in their fields.

Custom butcher paper positions itself as a versatile solution that laboratories and studios from various industries regularly use, with affordable prices and flexible properties. The practical and sustainable use of butcher paper extends to structural modeling as well as conceptual design and mock-up creation. The simple paper turns out to be an advanced prototyping tool that will shape the future design and fabrication processes.

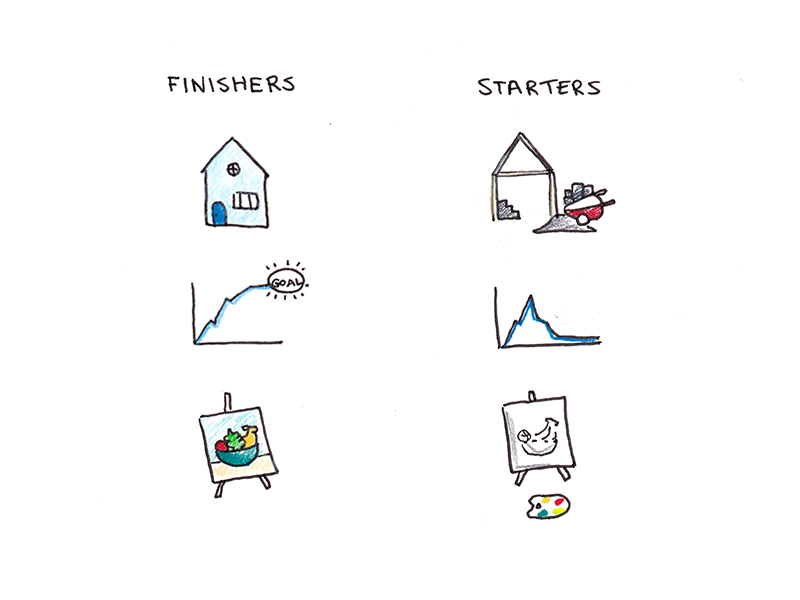

Prototyping Essential

The prototyping process requires three essential elements: high speed combined with precise work while using an iterative approach. The prototyping process benefits from custom butcher paper because its affordable nature and flexible texture make it perfect for this work method. The process of model construction using custom butcher paper sheets enables teams to develop prototypes quickly using any materials before implementing permanent ones.

Early-stage testing of new ideas quickens through immediate product evaluation while team members collaborate without delay. Such a level of paper customization transforms this tool into something more personal and valuable. As businesses continuously need reliable and budget-friendly stocks for developing new products, they frequently acquire large quantities of wholesale custom butcher paper.

A Sustainable and Flexible Solution for Designers

Selecting the correct materials has become increasingly important in our modern eco-dedicated environment. The main advantages of custom butcher paper extend beyond its operational benefits to include environmentally friendly characteristics. It is an eco-friendly material that can decompose naturally while featuring recyclable properties together with renewable material origins.

The sustainability of this material ensures its appropriate use in prototyping because it allows responsible disposal of materials after the development cycle. Creative professionals adopt this change by using custom butcher paper for food prototype testing, which allows them to check new designs before production without harming the environment.

From Sketchpad to Three-Dimensional Models

The ability to produce actual three-dimensional prototypes represents another strength of custom butcher paper in addition to its flat sketching capabilities. Due to its pliability, butcher paper shapes into packaging solutions such as boxes and then envelopes to mimic end-user interactions. Such packaging and retail design applications prove highly beneficial because of this functionality.

Designer-created butcher paper printed bags enable test scenarios that both replicate customer competition and retail setup to evaluate product effectiveness and user engagement. The iterative design process becomes smoother through the ability of paper prototypes to be easily modified or added layers.

A Game-Changer in Texture and Tactile Testing

The effect of texture remains one of the lesser-understood aspects throughout the prototyping process. The touchy texture of butcher paper resembles product surfaces after manufacturing. Touch characteristics require attention for all product packaging along with garment wrapping and menu holder designs.

Butcher wrapping paper functions as an essential tool for tactile user interaction testing, which allows teams to forecast the way future users will handle final products. The gap between visual appearance and sensory experience becomes bridged through this solution because customer perception rules all industries.

Enhancing Workflow with Pre-Cut Custom Sheets

The value of time becomes essential in all prototyping situations. Custom-printed wax paper plays a vital role in streamlining the workflow process. Team members can start working directly on creative tasks after skipping both the manual measuring and cutting process through pre-cut custom sheets.

The sheets offer standardized prototypes for scaled models and temporary design layouts to help users streamline their processes. These sheets minimize unnecessary material usage, which completely matches lean design strategies and rapid project cycle principles used today.

Branding Meets Functionality in Prototyping

The storytelling elements combine with form design purposes to shape the essential nature of prototyping. The visual elements, together with brand identity, remain essential factors that draw customers. Teams benefit from personalized butcher paper because it showcases how logos, taglines, and visuals appear like they would in genuine applications.

This approach offers stakeholders and clients unambiguous views about the packaging production outcome. The tool allows brand testing through focus groups, which assists companies in improving both their content and product delivery approach.

Educational and Collaborative Applications in Workshops

Professional design teams lead the current use of custom butcher paper, but educational and collaborative groups now recognize its value in their settings. Professional workshop courses within design schools, along with maker spaces and innovation hubs, routinely use custom butcher paper to instruct students about essential prototyping techniques as well as scale modeling and packaging design principles.

The combination of affordability and simplicity enables the tool to work exceptionally well in teams that need fast-moving idea formation during brainstorming periods. The lesson enables students to learn about dimensions, along with functionality and visual impressions, by using custom butcher paper bags in their packaging assignments. The tool brings out innovative concepts through experiential learning, which trains the necessary hands-on skills that companies need for modern product development.

Sum Up

Several rounds of testing through feedback cycles and modifications led to transforming ideas into commercial products. Custom butcher paper acts as an ideal tool that turns conceptual design elements into functional implementation methods. Designers can conduct crucial tests of their layout structures and the way products fold and seal by using custom butcher paper before final product production decisions.

The paper prototypes perform functions beyond static visual displays because they allow teams to conduct stress tests as well as handling assessments. Staff members use custom butcher paper sheets to replicate assembly lines while testing packaging characteristics along with customer unboxing scenarios before raw materials become involved.

Conclusion

Custom butcher paper has introduced itself to creative studios and prototyping labs, even though its original purpose was tied to delis and butcher shops. The combination of economical expenses, customizable features, and environmental friendliness establishes custom butcher paper as an essential development tool during product design phases. The common material provides vital benefits through both the development of new ideas and packaging simulations. This solution functions as a functional link that connects ideas and production methods. Custom butcher paper will likely emerge as a continuous force in Canadian prototyping grounds as well as global product development laboratories because of its adaptable and sustainable characteristics.

![Building A Digital PR Strategy: 10 Essential Steps for Beginners [With Examples]](https://buzzsumo.com/wp-content/uploads/2023/09/Building-A-Digital-PR-Strategy-10-Essential-Steps-for-Beginners-With-Examples-bblog-masthead.jpg)

![How to Use GA4 to Track Social Media Traffic: 6 Questions, Answers and Insights [VIDEO]](https://www.orbitmedia.com/wp-content/uploads/2023/06/ab-testing.png)