This vertical farming startup is bringing fresh produce—and international competitors—to the Dubai desert

When Sky Kurtz set out to grow produce in the desert via vertical farming in 2016, laying the groundwork for what became Dubai-based ag-tech startup Pure Harvest Smart Farms, “People thought we were crazy,” he says. “I was fearful, I would never get off the ground.” But Kurtz’s came at a time when the UAE was beginning to take the idea seriously and companies like Pure Harvest began cropping up. Over the past nine years, though, Pure Harvest Farms has become one of the sector’s biggest players. It has raised more than $450 million in funding, according to market analysis company PitchBook, and grows an array of crops that includes tomatoes, green vegetables, and berries in temperature-controlled facilities. With farms strategically located throughout the UAE, the company boasts the capacity to produce over 12 million kilograms of crops annually. Despite the competition, Pure Harvest has distinguished itself as the dominant player in the country’s indoor farming sector. Unlike other ag-tech companies which were designed for temperate climates, Pure Harvest developed technologies specifically built to withstand the harsh climates of the Middle East. Unlike other ag-tech companies that focus on niche produce and cater to premium markets, Pure Harvest sells a wide range of produce and supplies to major supermarket chains across the country. The UAE has rapidly become a global hub for ag-tech innovation, attracting diverse companies from around the world: U.S.-based Plenty plans to open a vertical farm in Abu Dhabi by 2026 whereas AeroFarms launched the world’s largest indoor vertical farm in Abu Dhabi in 2023. As companies from abroad come to the UAE, Pure Harvest is expanding its vision. It’s currently in the midst of raising at least $100 million to expand operations into Singapore, Morocco, and Kuwait, and an initial public offering is possible in the coming years. “I think the world has woken up that the problem that Pure Harvest Smart Farms is solving is acute and it is here now,” Kurtz says. Adapting to the region’s weather Global demand for efficient indoor food production globally is surging, given climate change disrupting traditional agriculture as water sources dry up and temperatures rise. In the United States the Colorado River—responsible for irrigating 15% of the nation’s farmland—is drying up rapidly. Meanwhile, across the Horn of Africa, prolonged droughts are responsible for more than 23 million people experiencing severe hunger. The Middle East, particularly the UAE, experiences brutal heatwaves, with less than 1% of the land suitable for agriculture. This makes the country heavily dependent on food imports, with over 80% of its food coming from abroad. Producing locally not only reduces the costs and carbon emissions associated with transportation but also makes the UAE less reliant on imports. The UAE is making huge strides to advance agri-tech in the country with an ambitious aim to improve hydroponic farming and source 70% of produce from local farms by 2025. This push toward local food production gained momentum during the COVID-19 pandemic, which severely disrupted global food imports—and what ultimately accelerated Pure Harvest’s success. “When COVID stopped travel, places that relied on the bellies of airplanes to move food around suddenly woke up to the fragility of their food supply chains,” says Kurtz, adding the pandemic prompted governments and markets into supporting agri-tech companies that produce efficiently and locally. Agri-tech companies like Pure Harvest Farms benefit from a unique geographical advantage in the UAE: Around 80% of the world’s population lives within an eight-hour flight of Dubai. This ideal location places them at the heart of a vast consumer base. “You know that expression: ‘skate to where the puck is heading’. We are building a company where the world’s population is growing . . . so we sit in a wonderful market position where there’s huge tailwinds,” says Kurtz. Beyond its strategic location, one key reason Kurtz chose Abu Dhabi as the base for Pure Harvest Smart Farms was his conviction that if the company could succeed in producing food in the “harshest environments in the world,” where temperatures can soar to 125° Fahrenheit, it would prove the credibility and capability of his company to produce food anywhere in the world. With ambitions for worldwide expansion, Kurtz aimed to first prove that the technology could thrive in such extreme conditions. “If you think of the problem of climate affecting food, resource scarcity, water scarcity, what’s worse than the Middle East?” Kurtz says. “I mean, this is literally ground zero.” Another factor making UAE an attractive hub for Pure Harvest was the country’s funding for startups trying to solve the region’s pressing issues. “When I first came out trying to pitch people on, you know, I had a PowerPoint, a pile of dirt and the promise of what we were going to build,”

When Sky Kurtz set out to grow produce in the desert via vertical farming in 2016, laying the groundwork for what became Dubai-based ag-tech startup Pure Harvest Smart Farms, “People thought we were crazy,” he says. “I was fearful, I would never get off the ground.”

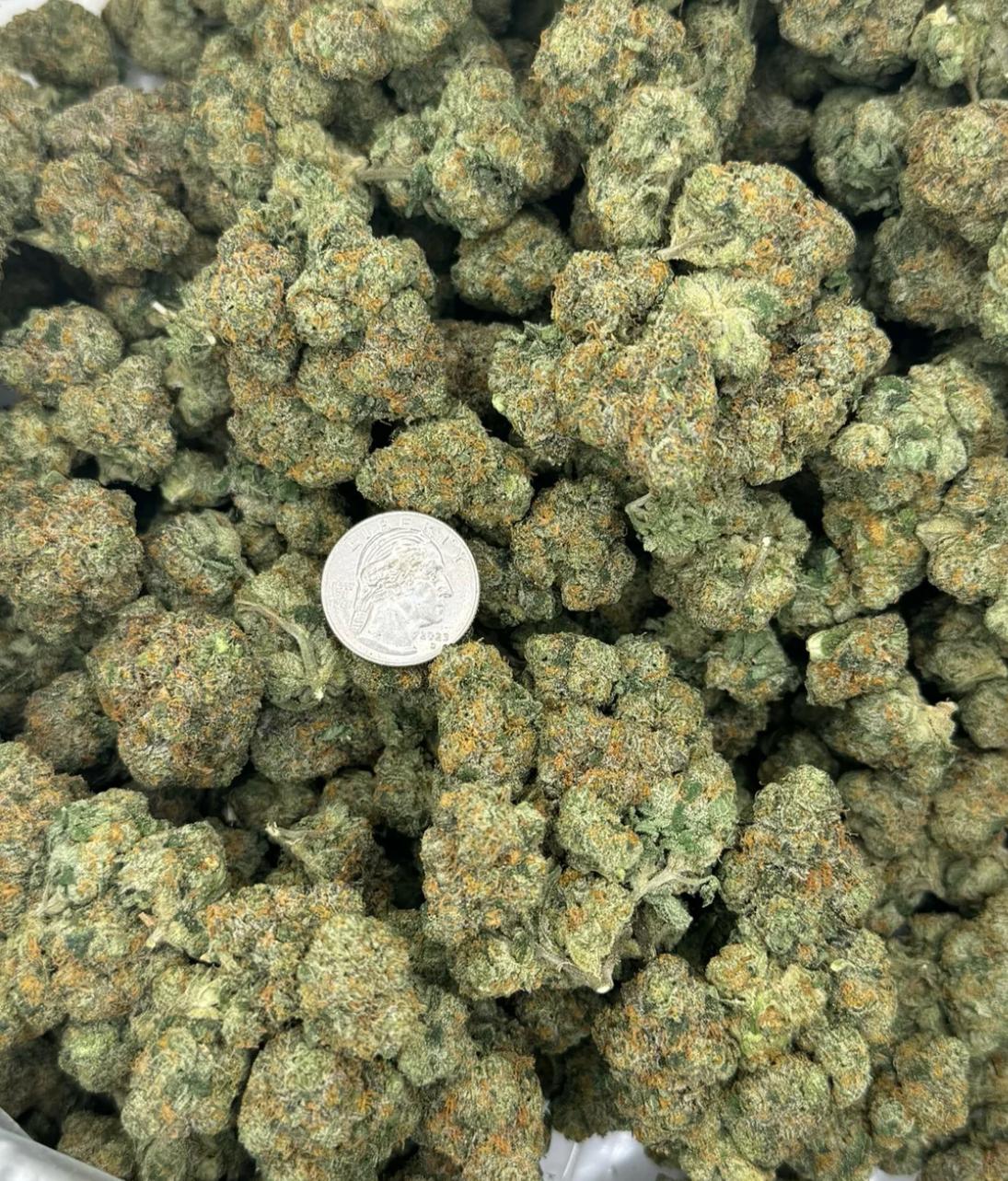

But Kurtz’s came at a time when the UAE was beginning to take the idea seriously and companies like Pure Harvest began cropping up. Over the past nine years, though, Pure Harvest Farms has become one of the sector’s biggest players. It has raised more than $450 million in funding, according to market analysis company PitchBook, and grows an array of crops that includes tomatoes, green vegetables, and berries in temperature-controlled facilities. With farms strategically located throughout the UAE, the company boasts the capacity to produce over 12 million kilograms of crops annually.

Despite the competition, Pure Harvest has distinguished itself as the dominant player in the country’s indoor farming sector. Unlike other ag-tech companies which were designed for temperate climates, Pure Harvest developed technologies specifically built to withstand the harsh climates of the Middle East. Unlike other ag-tech companies that focus on niche produce and cater to premium markets, Pure Harvest sells a wide range of produce and supplies to major supermarket chains across the country.

The UAE has rapidly become a global hub for ag-tech innovation, attracting diverse companies from around the world: U.S.-based Plenty plans to open a vertical farm in Abu Dhabi by 2026 whereas AeroFarms launched the world’s largest indoor vertical farm in Abu Dhabi in 2023.

As companies from abroad come to the UAE, Pure Harvest is expanding its vision. It’s currently in the midst of raising at least $100 million to expand operations into Singapore, Morocco, and Kuwait, and an initial public offering is possible in the coming years.

“I think the world has woken up that the problem that Pure Harvest Smart Farms is solving is acute and it is here now,” Kurtz says.

Adapting to the region’s weather

Global demand for efficient indoor food production globally is surging, given climate change disrupting traditional agriculture as water sources dry up and temperatures rise. In the United States the Colorado River—responsible for irrigating 15% of the nation’s farmland—is drying up rapidly. Meanwhile, across the Horn of Africa, prolonged droughts are responsible for more than 23 million people experiencing severe hunger.

The Middle East, particularly the UAE, experiences brutal heatwaves, with less than 1% of the land suitable for agriculture. This makes the country heavily dependent on food imports, with over 80% of its food coming from abroad. Producing locally not only reduces the costs and carbon emissions associated with transportation but also makes the UAE less reliant on imports.

The UAE is making huge strides to advance agri-tech in the country with an ambitious aim to improve hydroponic farming and source 70% of produce from local farms by 2025. This push toward local food production gained momentum during the COVID-19 pandemic, which severely disrupted global food imports—and what ultimately accelerated Pure Harvest’s success. “When COVID stopped travel, places that relied on the bellies of airplanes to move food around suddenly woke up to the fragility of their food supply chains,” says Kurtz, adding the pandemic prompted governments and markets into supporting agri-tech companies that produce efficiently and locally.

Agri-tech companies like Pure Harvest Farms benefit from a unique geographical advantage in the UAE: Around 80% of the world’s population lives within an eight-hour flight of Dubai. This ideal location places them at the heart of a vast consumer base. “You know that expression: ‘skate to where the puck is heading’. We are building a company where the world’s population is growing . . . so we sit in a wonderful market position where there’s huge tailwinds,” says Kurtz.

Beyond its strategic location, one key reason Kurtz chose Abu Dhabi as the base for Pure Harvest Smart Farms was his conviction that if the company could succeed in producing food in the “harshest environments in the world,” where temperatures can soar to 125° Fahrenheit, it would prove the credibility and capability of his company to produce food anywhere in the world. With ambitions for worldwide expansion, Kurtz aimed to first prove that the technology could thrive in such extreme conditions. “If you think of the problem of climate affecting food, resource scarcity, water scarcity, what’s worse than the Middle East?” Kurtz says. “I mean, this is literally ground zero.”

Another factor making UAE an attractive hub for Pure Harvest was the country’s funding for startups trying to solve the region’s pressing issues. “When I first came out trying to pitch people on, you know, I had a PowerPoint, a pile of dirt and the promise of what we were going to build,” says Kurtz, recalling that initial support came from the Mohammed bin Rashid Innovation Fund, which provided a $1.5 million loan. The Abu Dhabi Investment Office has played a pivotal role by offering significant financial support through grants.

Indoor farming’s growing scope

Pure Harvest is no longer the only player in indoor farming. It has spearheaded a growing sector that now includes companies like Below Farms, which leverages temperature controlled indoor environments to produce over 120 tonnes of premium mushrooms annually. Below Farms leverages controlled-farming environments in the UAE to grow premium mushrooms in the desert, with a capacity of 120 tonnes annually.

Beyond efficiency, Bronte Weir, founder of Below Farms, emphasizes that indoor farming can produce food of superior quality compared to traditional methods. He notes that vegetables start losing their nutrients at an increasing rate after harvest, and when they are exported and consumed days later, they “are not going to be as good as when it’s harvested 100 or 50 kilometers down the road.”

Below Farms mushrooms are currently purchased by several fine dining restaurants across the UAE such as Emirates Palace and Atlantis. Mushrooms, in particular, have a short shelf life and are extremely perishable due to their high-water content—which Bronte says makes local production especially advantageous. “We’re harvesting pretty much straight into the kitchen,” he says.

At Pure Harvest, the company has has begun getting creative about how to expand its offerings. It has launched a line of all-natural strawberry preserves and tomato sauces, made from surplus seasonal produce, an effort to turn potential food waste into premium products. Kurtz says the company’s growing ambition—and goal of becoming a household brand in the next 50 years—goes hand in hand with responding to the world’s growing need to get creative about farming.

“It’s becoming a global dialogue about how are we going to secure the future of food in a world that will have nine and a half billion people,” he says, “that is not making more land, and where water security is now becoming a crisis.”