This 3D-printed train station in Japan took less than 6 hours to build

Need a train station shelter in a hurry? You can now print that.In Arida, Japan, a Japanese architectural firm and 3D-printed house manufacturer partnered with JR-West, a railway network, to build what they claim is the world’s first 3D-printed train station. Assembled in less than six hours between the station’s last train of the night and first train of the following morning, it’s a promising first look at how infrastructure improvements might be done faster and cheaper.[Image: West Japan Railway]The station is the work of the 3D-printed house manufacturer Serendix and the architecture studio Neuob. It’s made from four 3D-printed mortar pieces that were printed offsite and filled with concrete for reinforcement before being assembled. The final building footprint is just more than 100 square feet, and replaces an older wooden shelter at Japan’s Hatsushima Station outside Osaka. While the facade is in place on site, the overall structure is still a work in progress as ticket machines and transportation card readers still have to be installed ahead of its official July opening.[Image: Serendix Inc.]The shelter’s pieces were purposefully printed so that the indention between each printed layer would be vertical rather than horizontal when assembled. This reduces “the visibility of rain streaks and improves the building’s maintenance properties,” the company told Dezeen. The construction style also allows manufacturers to embed custom embellishments into a wall as it is produced; in this case a mandarin orange shape representative of local produce in the region.[Photo: Serendix Inc./Neuob Inc.]This isn’t Serendix’s first 3D structure within tight time constraints: The company also built a 3D-printed house called “Sphere” in 2022 in just under 24 hours. With this 3D-printed train station, the company proves how fast workers can install a prefabricated building. It also builds proof of concept for a new paradigm about construction that’s faster and cheaper in a time of rising costs. With construction needs for buildings like new homes or repairs on aging infrastructure on the rise, 3D-printed buildings could provide builders with cheaper and faster building methods and materials to meet demand.

Need a train station shelter in a hurry? You can now print that.

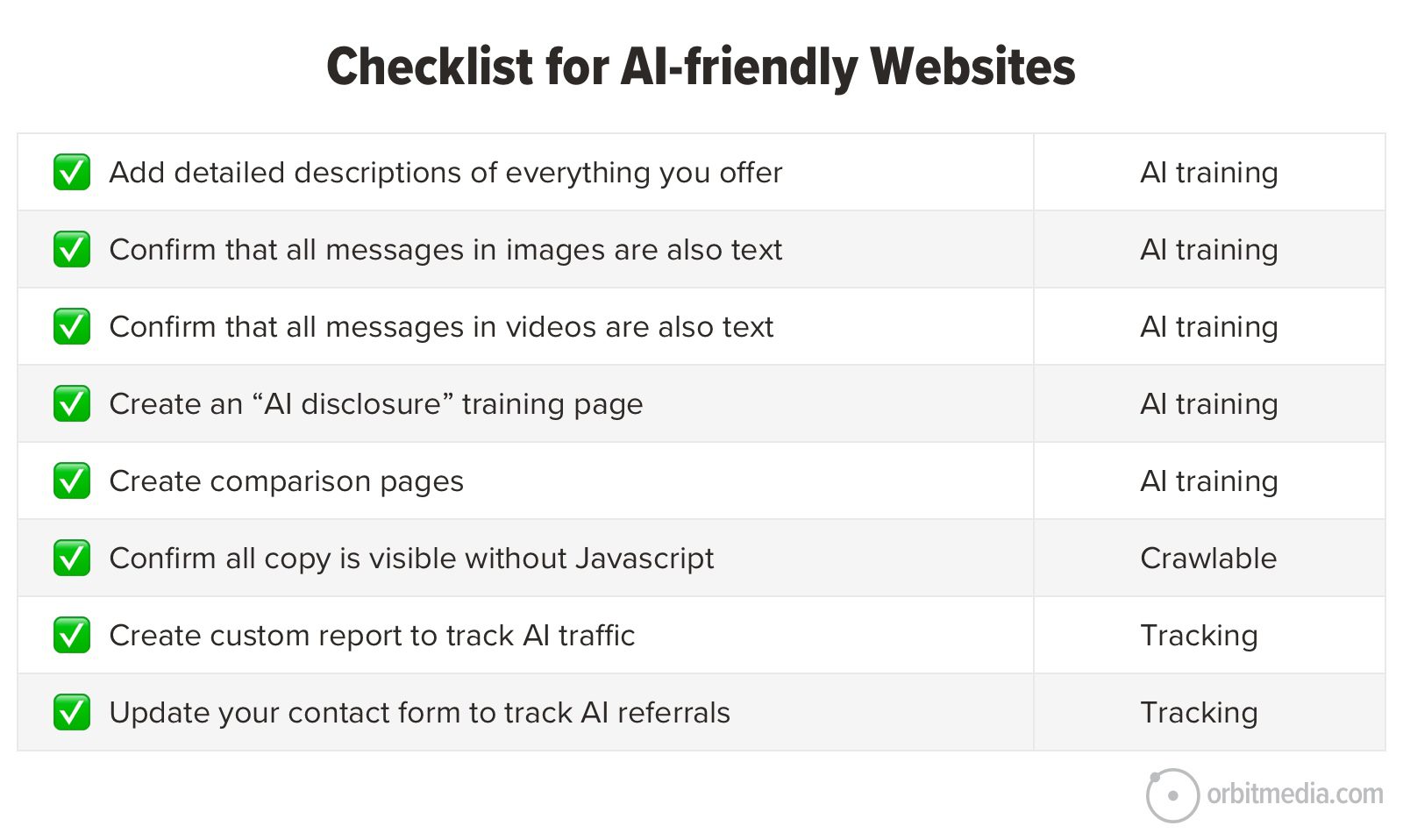

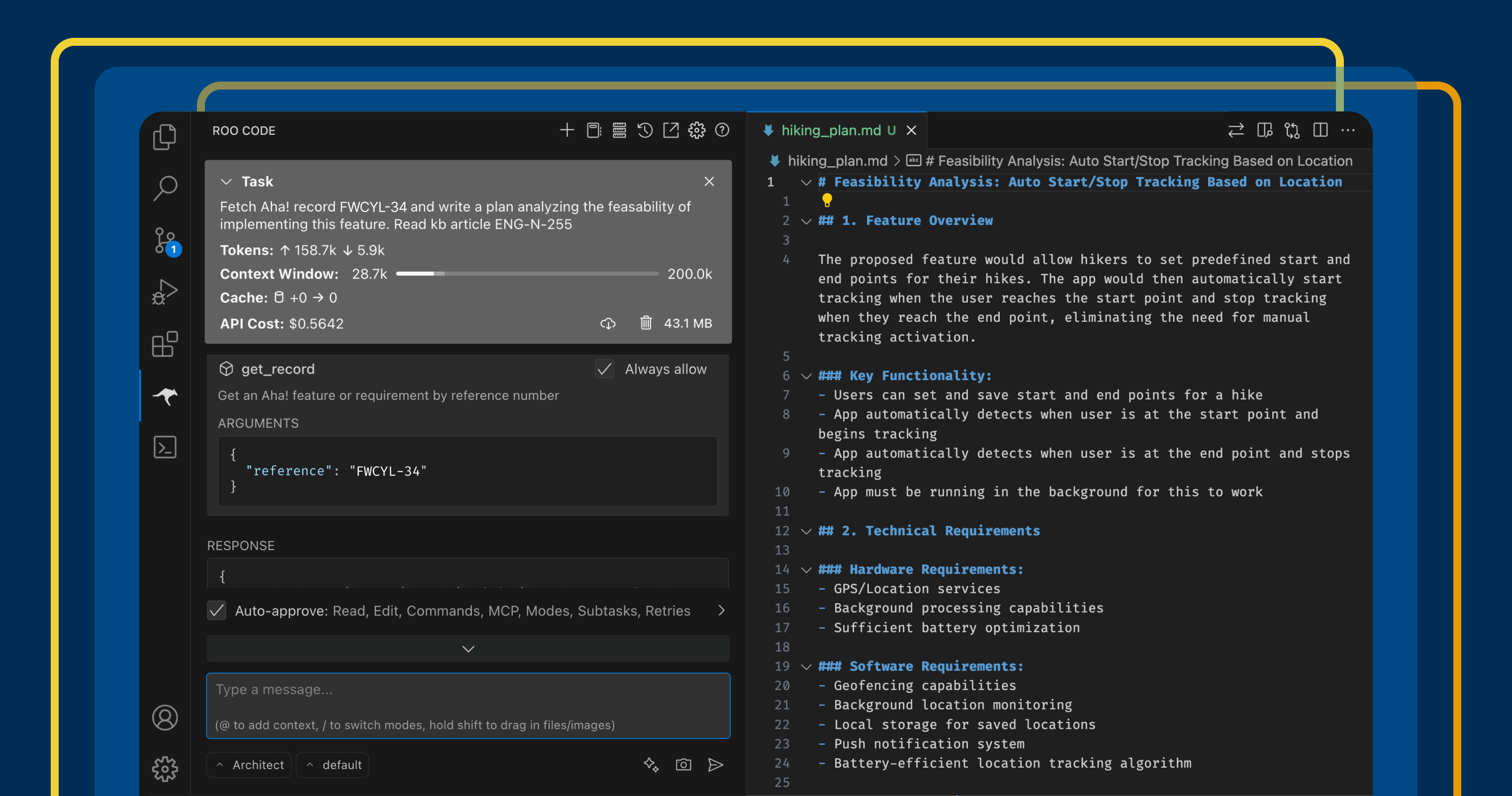

In Arida, Japan, a Japanese architectural firm and 3D-printed house manufacturer partnered with JR-West, a railway network, to build what they claim is the world’s first 3D-printed train station. Assembled in less than six hours between the station’s last train of the night and first train of the following morning, it’s a promising first look at how infrastructure improvements might be done faster and cheaper.

The station is the work of the 3D-printed house manufacturer Serendix and the architecture studio Neuob. It’s made from four 3D-printed mortar pieces that were printed offsite and filled with concrete for reinforcement before being assembled. The final building footprint is just more than 100 square feet, and replaces an older wooden shelter at Japan’s Hatsushima Station outside Osaka. While the facade is in place on site, the overall structure is still a work in progress as ticket machines and transportation card readers still have to be installed ahead of its official July opening.

The shelter’s pieces were purposefully printed so that the indention between each printed layer would be vertical rather than horizontal when assembled. This reduces “the visibility of rain streaks and improves the building’s maintenance properties,” the company told Dezeen. The construction style also allows manufacturers to embed custom embellishments into a wall as it is produced; in this case a mandarin orange shape representative of local produce in the region.

This isn’t Serendix’s first 3D structure within tight time constraints: The company also built a 3D-printed house called “Sphere” in 2022 in just under 24 hours. With this 3D-printed train station, the company proves how fast workers can install a prefabricated building. It also builds proof of concept for a new paradigm about construction that’s faster and cheaper in a time of rising costs. With construction needs for buildings like new homes or repairs on aging infrastructure on the rise, 3D-printed buildings could provide builders with cheaper and faster building methods and materials to meet demand.

![Building A Digital PR Strategy: 10 Essential Steps for Beginners [With Examples]](https://buzzsumo.com/wp-content/uploads/2023/09/Building-A-Digital-PR-Strategy-10-Essential-Steps-for-Beginners-With-Examples-bblog-masthead.jpg)

![How One Brand Solved the Marketing Attribution Puzzle [Video]](https://contentmarketinginstitute.com/wp-content/uploads/2025/03/marketing-attribution-model-600x338.png?#)